产品技术支持

联系人:郭 旺

手机:18020201599

传真:0512-50169299

邮箱:pascal_guo@163.com

1. 工艺参数要求 Process Data Requirement

|

PROCESS DESCRIPTION 制程描述 |

溶剂浓缩和真空干燥 (制程物:乙酸酐、乙酸、甲醇、乙醇、二氯甲烷、盐酸、甲基叔丁基醚、四氢呋喃、丙酮、正庚烷、乙酸乙酯、水等有机溶剂) |

||

|

Suction speed 抽气速率 |

70 L/S |

||

|

Ultimate pressure 极限真空 |

要求设备使用端压力能够达到200Pa以下,设备本身极限真空5Pa以下 |

||

|

Voltage 电压 |

3相,380V |

||

|

Type of construction 结构型式 |

Vacuum Unit skid mounted |

||

|

Hazard category (ATEX) 防护等级 |

ExdIIBT4 |

|

|

2. 技术方案 Technical Proposal

根据工艺要求,推荐使用汉钟旗下著名真空品牌产品,PD300干式螺杆真空泵组,配置7.5KW风冷变频防爆马达。采用汉钟干式螺杆真空泵,有如下优势:

1、 底压好,单泵可达1Pa;

2、 运行稳定,噪音低;

3、 节能,实际功耗低于5KW;

4、 密封性能佳,密封形式选用高低压端唇型密封+活塞环+氮封,密封可靠.

过流部分O-ring采用PTFE包覆VITON材质;

5、 真空泵系统配置电控,允许显示螺杆泵壳体温度,水流量,

带壳温、电机温度、过载、水流量过低保护等;

6、 系统配置总运行时间,开机时间显示,报警记录;

7、 电控系统含PLC,HMI,预留DCS通讯;

8、 停机吹扫动作:自动打开电磁阀1持续通入氮气15min(此时间可调节)电磁阀1关闭。关闭防爆电磁阀2与防爆电磁阀3,系统停机。

- 真空泵(机组)的技术特性Characteristic of vacuum package

|

机型Model |

单位Unit |

PD300 |

|

|

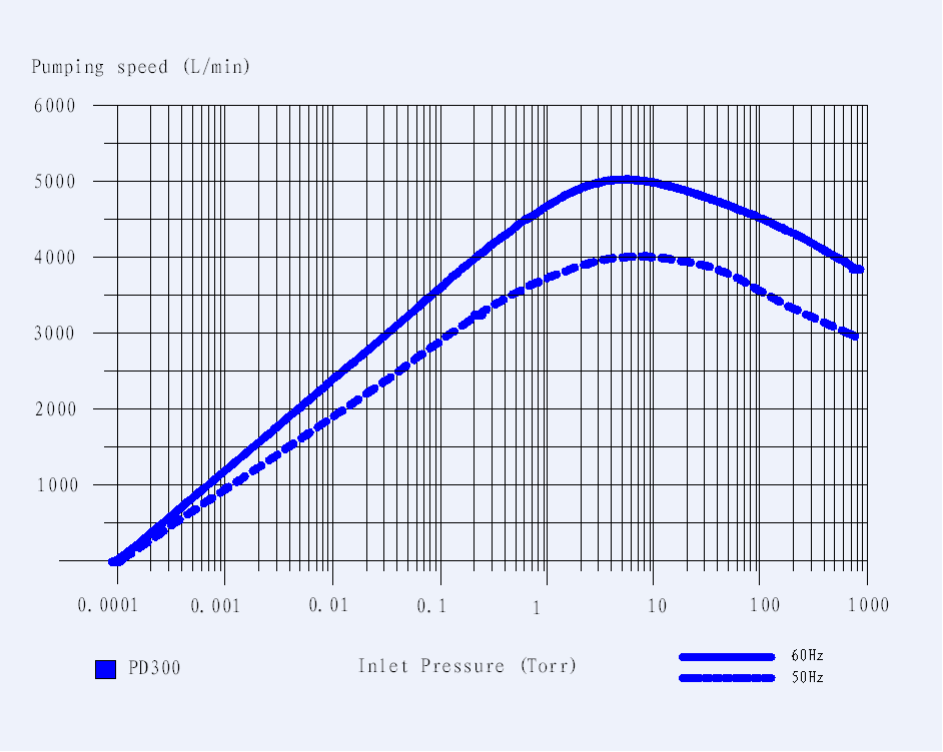

抽气速度 Pumping Speed (50Hz/60Hz) |

l/min |

4167 / 5000 |

|

|

m3/hr |

250 / 300 |

||

|

Cfm |

147 / 176 |

||

|

终极压力 Ultimate Pressure |

Torr |

≦7.5×10-3 |

|

|

mbar |

≦1×10-2 |

||

|

Pa |

≦1 |

||

|

马达 Motor |

频率Frequency |

Hz |

50/60 |

|

电压Voltage |

V |

220/380 |

|

|

额定功率 Rated Power |

Hp |

10 |

|

|

kW |

7.5 |

||

|

连接 Connection |

进气口Inlet |

|

DN65 |

|

排气口Outlet |

|

DN40 |

|

|

冷却水 Cooling Water |

流量Min. Flow |

l/min |

20-30 |

|

温度temperature |

℃ |

15-30 |

|

|

压力Pressure |

Mpa |

0.2-0.4 |

|

|

接头Connection |

|

RC 3/8" |

|

|

氮气 N2 |

压力Purge Pressure |

MPa |

0.15-0.2 |

|

流量Purge Flow |

Slm |

0-60 |

|

|

接头Connection |

|

Swagelok 1/4" |

|

|

重量Weight |

Kg |

500 |

|

|

噪音Noise |

dB(A) |

<80 |

|

|

系统最大漏率 System Max. Leak-rate |

mbar.l/s |

<1×10-5 |

|

|

室温操作范围Operation Temp. |

℃ |

5℃~40℃ |

|

|

操作湿度Operation Moisture |

RH |

90%以下 |

|

- 机组配置 Package configuration

- 驱动电机为直联防爆电机,7.5kw/380v

Direct driven motor by ex-proofed van-cooled frequency motor 7.5kw/380v

- 真空泵过流部件高镍磷涂层

Ni-P coating for process parts

- 氮气密封保护和停机清洗吹扫

Nitrogen-sealed protection and pump stop purge

- 排出管路配有不锈钢消音器可以降低噪音

Stainless Steel Silencer mounted at exhaust line for reduce the noise

- 整套真空机组会安装在碳钢焊接底座上成为一体

- The vacuum pumps, motors, valves, instruments, pipe-works will be mounted on a carbon steel base as a skid.

3. Technical Specifications and Description 技术参数和配置详述

3.1 Dry Screw Vacuum Pump螺杆真空泵组PD300

PD300为双级压缩,水冷式,无油干式螺杆真空泵,特殊的螺杆设计确保干泵低温且高效运行。

PD 300 is a double stage, water cooled, dry running screw vacuum pump. The special

designed screw gives high efficiency and low internal temperatures.

它的主要特点如下:

Its major features are :

低温,干式,无油无水的纯净系统运行,可大大减少污染。

- Cool, Dry running, oil and water free pumping, to minimise pollution.

无接触式压缩,可确保无磨损运行。

- Non-contact compression for wear free operation.

对液体有一定的兼容性,适合抽取冷凝性气体,及一定量的固体颗粒杂质。

- High tolerance to proper liquid carry-over, condensate and process solids.

允许就地使用氮气,合适的蒸汽,溶剂等冲洗泵体。

- Designed to allow cleaning in-situ, with N2, steam, solvent etc.

高低压端唇封,结合迷宫式密封及氮封

- Lip-seal combined with labyrinth seals and N2 sealing

操作使用方便,几乎免维护。

- Easy to operation, almost no maintenance.

3.2水冷系统Cooling System:

水冷系统,通过外接冷却水来冷却泵体,最大限度的保护了真空泵,避免了温度过高对泵产生的不良影响;

The water cooling system uses the fresh cooling water to cool the pump case, it mostly protect the pump damage from the higher temperature.

真空泵冷却水流量:不少于5 L/min

Cooling water for dry vacuum: No less than 5 L/min

冷却水进水温度:15~30℃

Temperature of the cooling water supply: 15~30℃

冷却水供水压力:2-4 bar,排水无背压

Pressure of the cooling water supply: 2-4 bar, water return no pressure

3.3 氮气吹扫系统Nitrogen purge system

进气口气体吹扫接口,可根据实际工艺情况选择使用。干燥氮气吹扫有利于帮助将可凝性气体彻底排出。也可用于低温条件下帮助预热真空泵。

One port for pump stop purge at the pump inlet, customer can choose use it or not. Nitrogen purge is helpful for removing the condensate, and it also can help to warm the pump under low temperature.

氮气密封保护可有效防止工艺气体从泵腔密封处泄漏到油箱使润滑油性能下降造成对泵的损坏。

Nitrogen-sealed protection purge can prevent the process gas leaking to the oil box then damage the pump by decreasing the capability of the oil.

-氮气吹扫管路路附件Nitrogen purge system piping connection:

N2 pressure gauge

N2 pressure regulator

3.4排气消音器及排气止回阀, Discharge silencer and Discharge check valve

排出管路配有不锈钢消音器,降低噪音.排气止回阀,防止气体返流。

Discharge silencer at discharge line will reduce noise and discharge check valve avoid the gas sucked back

4.机组供货范围(单套) Scope of Vacuum Package(1set)

|

序号No. |

项目 Items |

数量 Qty. |

|

1 |

PD300-S 螺杆真空泵,高镍磷涂层 PD300-S Dry screw vacuum pump units, Ni-P coating |

1 |

|

2 |

N2压力表 N2 pressure gauge |

2 |

|

3 |

N2调压阀 N2 pressure regulator |

2 |

|

4 |

目视化氮气流量计 Visual nitrogen flow gauge |

1 |

|

5 |

防爆水流量计 Ex-proofed water flow switch |

1 |

|

6 |

水温表 Water temperature gauge |

1 |

|

7 |

温控阀 Case temperature control valve |

1 |

|

8 |

防爆电磁阀-氮气 Ex-proofed solenoid valve for nitrogen |

2 |

|

9 |

防爆电磁阀-冷却水 Ex-proofed solenoid valve for cooling water |

1 |

|

10 |

防爆进气阀 Ex-proofed inlet valve |

1 |

|

11 |

防爆壳体温度感测器 Ex-proofed case temperature sensor |

1 |

|

12 |

防爆电机7.5Kw *380V*50Hz,含PTC Ex-proofed motor 7.5Kw *380V*50Hz,with PTC |

1 |

|

13 |

不锈钢排气消音器SUS316L Discharge silencer |

1 |

|

14 |

不锈钢排气止回阀SUS316L Stainless steel check valve |

1 |

|

15 |

不锈钢管道、管件SUS316L Stainless steel pipe & fittings |

若干 a few |

|

16 |

碳钢机架,垫片、螺栓等五金件 CS base, gasket, blot etc. |

若干 a few |

备注1:过流O-ring采用FEP/PFA结合FFKM。

分项报价清单

|

序号No. |

项目 Items |

数量 Qty. |

|

|

17 |

10合1防爆电控,含PLC,HMI Ex-proofed electronic control |

1 |

|

|

18 |

进气过滤器 Inlet filter |

Teflon材质 |

1 |

|

SUS316L |

1 |

||

|

19 |

碳钢真空罐200L CS vacuum buffer tank 200L |

1 |

|

|

20 |

排气冷凝器2m2 Exhaust condenser |

钛材 |

1 |

|

SUS316L |

1 |

||

|

21 |

回收罐20L,SUS316L Recycle tanK |

1 |

|

|

22 |

配套系统管路,阀门SUS316L Suitable system pipes and valves |

1 |

|

5. 图纸资料交付 Documents Delivery

设备交付时,随机交付以下纸质资料各1套。

Document delivery (one set for each) along with the equipment

-维护使用说明书 Operation manuals

-工厂试验检验报告 Factory test report

-所有供货设备的合格证明 Qualification certificate for supply equipment

-竣工图 Completion drawing

6. 服务及质保 Service and Warranty

汉钟的售后服务体系提供“一天24小时,一周七天,全年365天”全天候无休服务。

Hanbell after service system provide “24 hours, 7 days of week, 365 days of year”, no break service.

汉钟的服务工程师都经过专业培训,在工业领域具有极高的维修水准,他们具有足够的技能对转动设备、电气控制面板、整个系统与过程进行维修与保养。中国的技术工程师会在8小时内对工艺技术问题给出响应,全球技术支持体系会在24小时内对疑难问题做出响应。如遇现场需要或紧急情况,汉钟服务机构会火速派遣工程师24小时内到达客户现场,用最先进的通讯手段来联络和调配服务工程师。

All the hanbell service engineers are special trained. They all reached high service level in industry field, and they are full of skills to repair and maintenance the power equipment, control system and the package. Hanbell China technical engineers will be response the technical problem within 8 hours, hanbell all world support system will be response the troubles and difficult within 24 hours. If there is request or emergency situation on site, hanbell service department will arrange service engineers to customer’s site within 24 hours. There is most advanced communication system in hanbell for contact and arrange the service engineers.

位于上海的制造中心、服务中心和备件仓库能给用户在售后服务上提供坚定的承诺和强有力的支持,以最优的价格提供正牌配件。同时,我们的服务工程师会定期与客户沟通了解设备运行情况,并经常到现场拜访。

The manufacture center, service center and spare parts warehouse which located Shanghai will provide the stable promise and strong support, and will provide the standard brands spare parts with preferential price. At the same time, our service engineers will contact with the customer and find out whether the equipments are all right commonly, even often go to visit the customer.